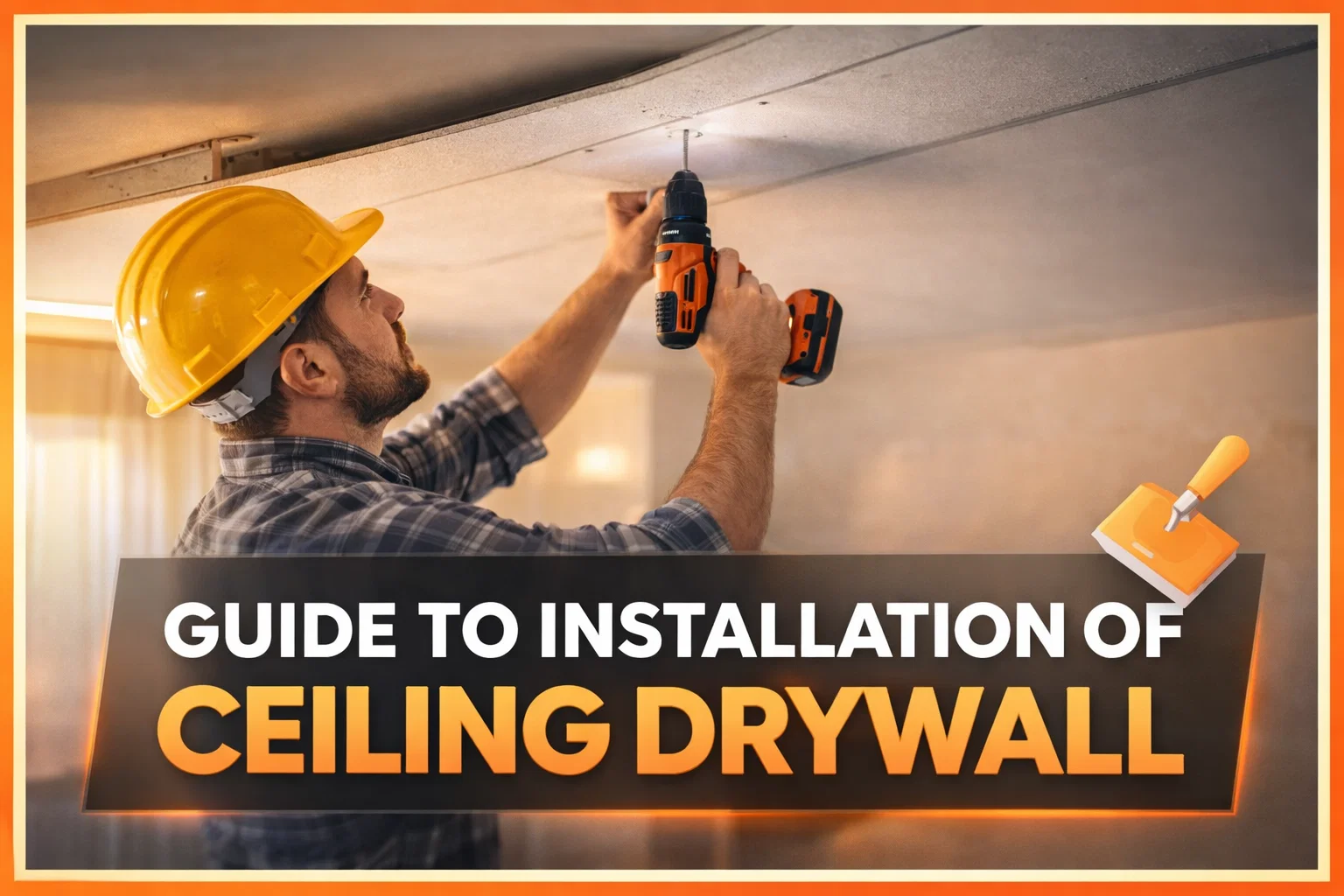

Installing ceiling drywall is not a difficult task, but it takes some effort to do it right. In case of getting it wrong, you will be left with flapping panels and visible seams. As soon as it is seen, all the errors stare back at you. If you are still having to deal with shaky panels and poor joints, then you are complicating the task more than it should be.

Our step-by-step instructions on drywalling a ceiling can help you do it yourself – in a manner that ensures your roof is clean and sturdy enough to not become an expensive embarrassment.

Prepare the Materials and Ceiling

You should have everything in place before putting up the drywall on the ceiling. Identify the points of the wooden supports you have in your ceiling and take all your tools, including a machine to move the dry wall up and metal fasteners.

Mark Joists for the Right Placement

Locate ceiling joists and label the locations. Use a tape measure to determine the distance between one end of the ceiling and the middle of a joist. Measure the size of your hanging drywall sheet to this size.

Make sure that there are markings so that they do not lose track during the subsequent step of gluing the drywall.

Use a framing square to be precise in angles on joist markings. Make sure that your lines run straight in order to make them appear professional. Screws are placed 0.375 inch away from the boundaries so that the drywall is firmly attached without any damage done to it.

Keep a uniform distance of 16 inches between the joists to exhibit stability and uniformity of your work.

Get Necessary Tools, Including a Drywall Lift and Screws

The proper equipment is important to install drywall on your ceiling. A drywall lift and screws come in handy. The lift supports the pieces of drywall such that you can attach them to the joists without interruption.

In the case of a 4×8 piece of drywall for ceiling, it is recommended that around 48 screws be used. This will entail the installation of screws at every 6 to 8 inches of the periphery and 12 inches of the central parts.

Kindly procure an impact driver and a drill. These make the assembly of screws easier and faster. Prepare some joint compound and drywall tape as well, to be used later and provide a fine finish.

The appropriate use of these mechanisms will help to provide sufficient strength to the boundaries of your ceiling drywall and to sustain it.

Hang Drywall on the Ceiling

The glue and use of screws are necessary to secure the drywall on the ceiling. Do not forget to place the sections in an alternate pattern; this is a precautionary measure against crack formation.

Stick The Ceiling Sheetrock With Adhesives and Screws

Your ceiling requires adhesive and screws to install the drywall. Apply glue on the joists first. This action ensures that the drywall sheet is adhered properly before the screws are attached. The second thing to do is to put the sheet of drywall on the ceiling and fix the drywall in place.

Next, nail the drywall down with coarse screws. Install these screws 7 inches around the edges of each sheet and 12 inches around the inside joists. Ensure that they are not pressed too deeply and that they are not buried through the paper surface.

This process makes your ceiling strong over an extended period of time.

Glue and screws will make a solid fix, which will not be hanging or falling. It is a creative tip that can ensure that your work is everlasting and presentable.

Stagger Seams to Avoid Cracking

Sheetrock ceiling can be made stronger by staggering Seams. Begin the second row with a half sheet to counter the joints. This technique prevents the occurrence of large cracks in the future. Ensure that tapered edges are joined to tapered edges so that the number of joints is reduced.

To have fewer cracks, do not place seams over door and window corners. And do not install butt joints in the middle of the ceiling. Whenever using ceiling panels, make sure that they are hung first, then the wall sheets are used to hold the edges better.

This is a trick that helps to make your work last longer as it resists the annoying cracks and splits.

Finish the Installation

Now it is time to get it smoothed out. Use tape and spackle along the joints, and sand them all smooth and even.

Spread the Seams With Tape and Mud to Create a Smooth Surface

In order to have a smooth drywall for the ceiling, apply fiberglass mat tape on every seam. You begin with the butted seams, then the long ones, and end with the inside corners. With a knife used in taping, press this tape into a heavy mix.

This ensures that your work remains flat and appears good.

Then another layer of mud is added over the tape. Your taping knife will again be used to smooth it. This is to conceal the tape, along with any small bumps or holes. Allow it to dry and continue.

And that is how making ceilings look professional takes time and attention to each detail.

Inspect and Sand Filler Up Holes

Once the joint compound has dried, it is time to sand. Apply a sponge or sandpaper. This action leaves the ceiling smooth. Search for bumps or depressions in the surface. Any there is, augment joint compound. Ensure that it is even and then wipe all the dust off the sanding.

Conclusion

With the right steps in place, ceiling drywall can be installed efficiently. Take the appropriate measurements. Use a panel hoister to position every drywall sheet. Then, apply adhesive and screw to make it durable. Implement alternating seams to avoid cracking. Finally, apply the tape and compound on them before sanding.

Or you can simply skip the hassle and contact Knapp Painting LLC to do the job with top professional expertise in Ohio.

FAQs

Ceiling drywall must always hang before the walls. In this manner, the wall sheets are capable of settling the edges of the ceiling panels and minimizing gaps.

Apply construction adhesive on the joists and drywall screws to have a safe ceiling.

Space screws about 7 to 8 inches apart along the edges and 12 inches apart in the field.